4 Applications and Importance of Vacuum Pumps

By Space Coast Daily // October 4, 2022

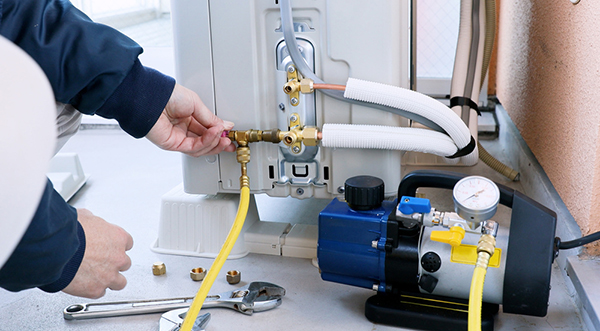

A vacuum pump is a mechanical device that eliminates gas molecules from a sealed volume to create a partial vacuum. It’s an essential tool in many processes, including freeze-drying, distillation, vacuum packaging, and more. In other words, vacuum pumps are critical in ensuring a smooth and efficient production process.

This, in turn, can produce quality and safe products.

A recent study found that the global vacuum pump market size is expected to reach USD$43.6 billion by 2026 at a compound annual growth rate (CAGR) of 4.6% during the forecasted period. This data shows the high demand for this mechanical device and its projected growth in the coming years.

You can find vacuum pump brands like Dpf Cummins Hats that have an excellent reputation for quality and performance. But before looking for the best vacuum pumps for your needs, here are four primary applications and the importance of vacuum pumps in different industries:

1. Chemical And Process Industries

Chemical and process industries use vacuum pumps for various purposes, such as removing vapors and fumes, distilling chemicals, and evaporating liquids. These procedures require a high degree of precision, and vacuum pumps help to achieve that.

How does it work? By providing the necessary suction to remove air or gas bubbles that could contaminate the chemicals in processes. Vacuum pumps also help to prevent explosions by keeping the environment around the chemical reaction under vacuum. This system is a crucial safety measure in any chemical plant.

2. Food And Beverage Industry

Did you know that around 30% to 40% of food supplies go to waste in the United States? Manufacturers can avoid this staggering amount of food with proper storage methods, such as vacuum packaging, freeze drying, and canning. These methods help to preserve food and extend its shelf life.

Here’s a quick overview of how each process works:

■ Vacuum Packaging

In the food and beverage industry, vacuum packaging is often used to preserve perishable goods, such as meat, dairy, and produce. This process removes the air from a package before sealing it. This system creates a partial vacuum around the food, preventing oxidation and bacteria growth, which can cause food spoiling.

■ Freeze Drying

As the name suggests, this method involves freezing food and removing the water content through evaporation. It uses sublimation principles wherein a solid goes directly to a gas state without passing through the liquid phase. This will preserve the food’s original shape, texture, and taste.

■ Canning

Vacuum pumps are also used in the canning process, a food preservation method involving sealing goods in an airtight container. This prevents bacteria and other microorganisms from contaminating the products.

All these applications are essential for food and beverage companies to maintain quality control and goods safety standards.

3. Pharmaceutical Industry

The pharmaceutical industry is a highly regulated sector with strict guidelines on manufacturing drugs. In a report, around 10% of global medicines could be substandard or falsified. This data is a serious concern as fake or subpar drugs can cause health complications, putting patients at risk.

Pharmaceutical companies must follow Good Manufacturing Practices (GMP) to ensure quality drugs. This includes using vacuum pumps in different stages of the manufacturing process, such as:

■ Distillation

Vacuum pump systems are used in the distillation process to remove impurities from the drug solution. This is done by boiling the solution at a lower temperature under a vacuum. The resulting product is a purer and more concentrated form of the drug. This makes it easier to separate the desired compounds from the mixture.

■ Sterilization

Sterilization is a process that helps to kill all microbes, such as bacteria and fungi. This is done by using steam under pressure or dry heat. Vacuum pumps are used in this process to remove air from the sterilization chamber, preventing the growth of microorganisms.

■ Degassing

This is the process of removing residual gases from the drug solution. This is important as it can affect the stability of the drug and its shelf life. Vacuum pumps help to create a vacuum around the solution, which removes the gases.

■ Crystallization

Crystallization is the application of heat and cooling to change a liquid into a solid crystal. The process purifies materials, obtains solids with the desired shape or physical properties, or produces solid solutions. Vacuum pumps pull the air out of the crystallization chamber, allowing the molecules to cool and solidify more rapidly. This results in larger, purer crystals.

4. Semiconductor Industry

The semiconductor industry relies on vacuum pumps to create the clean and controlled environment needed for manufacturing. Vacuum pumps are used in a variety of applications, including:

■ Lithography

One of the most crucial semiconductor manufacturing processes is lithography. Vacuum pumps eliminate air molecules from the area between the substrate and the photomask to create integrated circuits. This is important as the air molecules can interfere with the light used to create the circuit patterns on the substrate.

■ Thin Film Deposition

Thin film deposition is depositing a thin film of material onto a substrate. This is done by evaporating the material in a vacuum chamber and then condensing it onto the substrate. Vacuum pumps maintain the chamber at the correct pressure for the material to evaporate and condense onto the substrate. As a result, the film is evenly deposited with the desired thickness.

■ Etching

Etching is the most common use for vacuum pumps in the semiconductor industry. This process removes impurities from the surface of silicon wafers. The wafers are placed in a chamber and exposed to a plasma created by the vacuum pump. The plasma bombards the wafer and etches away impurities.

Conclusion

As you can see, vacuum systems have various applications in different industries. They’re essential in ensuring that processes are carried out efficiently and effectively. Remember to choose the right vacuum pump for your specific application to ensure optimal performance.