What is Machining Services China and What are its Benefits?

By Space Coast Daily // December 8, 2022

What is machining services china and what are its benefits? Machining Services China are cutting tools that are designed for both roughing and finishing operations.

They can be used to cut a wide range of materials, including metals, plastics, glass, ceramic and stone.

Machining services china offer a number of benefits to business owners, including:

Minimised wastage. Efficient use of raw materials. Lower production costs. Faster production times. Improved quality control processes.

There are many different types of machining services available in China which have been developed over many years by expert engineers who have studied the needs of various industries within the country. These include:

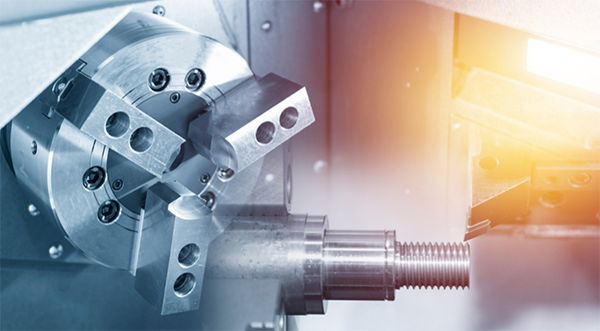

Lathe machining services – this involves using a lathe to turn round objects such as metal rods or bars into different shapes using a tool called a “turning tool”.

Lathes may also be used to make parts from flat plates by turning them on their side or end as well as performing other tasks such as drilling holes in them using a drill bit attached to the spindle at one end of the machine.

Lathes can be used for both small batch production runs and mass-production jobs depending on how much capacity you need from your machinery at any given time.

Lathes are used to make many parts for different products including cars, trucks, motorcycles and other vehicles.

These include things like brake calipers, steering wheels and even the engine block itself.

What industries typically use machining services china ?

Machining services are used by a wide range of industries. Common examples include the automotive industry and medical industry.

Many companies rely on machining services to produce parts that they can use in their manufacturing processes. The process is usually done by machine shops that specialize in machining services china.

The process involves taking a block of material, cutting it into a desired shape and then polishing it so that it meets specific tolerances.

Machining Services China – Manufacturing Process

Machining can be done either manually or automatically depending on the type of work needed by the customer. In some cases, machines may have been designed specifically for this purpose while other times they may just be modified versions of existing equipment.

Machining Services China – Material Types Used

There are many different types of material that can be used when performing machining services china including steel, aluminum, plastic and more.

Each material has its own set of requirements which must be met before any work can be done on them especially when you’re dealing with large pieces like car parts or machinery parts where tolerances must be kept within close limits so as not to cause problems later down the road when using them on an assembly line or in other applications where these parts will be used in.

The type of material used can also affect the cost of the machining services china which is why it is important to know what materials you will be using before making a final decision on which company to go with.

How does the process of machining work, and what machines are used to do the job?

Machining is the process of creating parts by cutting away material. It’s used to create many different types of parts, including gears, shafts, and bearings.

Machining was first developed as a way to make small metal parts for machinery, but it has evolved into a huge industry that makes many other kinds of products.

Machining involves using tools called cutting tools to remove material from a workpiece. Cutting tools include milling cutters, grinding wheels and abrasive discs, saw blades and drill bits.

The cutting tool is mounted in a machine tool and moved along the workpiece with a feed mechanism that advances it at a constant rate (known as the feed rate). The distance between the cutting tool and the workpiece is known as depth of cut or depth of engagement.

When you move an object through space, there are three basic ways in which it can move: translation (moving without changing shape), rotation (spinning around an axis), or oscillation (moving up and down like a spring).

When you move an object in any direction, there’s only one point on any given object that remains stationary. This point defines what we call zero degrees position (or ZDP).

What materials can be machined, and what are the limitations of this process?

The materials that can be machined are those that have a crystalline structure. These include metals and plastics.

The limitations of this process are:

1. The material must be solid, i.e., it cannot be hollow or porous.

2. The material should have a low coefficient of thermal expansion so as not to warp during machining.

3. The material should not be too brittle so as to break while being worked on by the machine tool.

4. The material should be free from inclusions (such as impurities, dirt and chips), which can cause the cutting tool to break or chip.

5. The material should be free from surface contaminants, such as oil and grease.

6. The machined part should be free from stress risers, which can cause cracks to form when the material is stressed by thermal expansion or contraction.

How accurate are the finished products, and how much tolerance is allowed for errors during the manufacturing process ?

The manufacturing process is very accurate, and the tolerances are very small. The finished product can be as little as 1mm off, or as large as 10mm off.

This means that if you order a 200mm x 200mm piece of granite, it can be anywhere from 199mm x 199mm to 209mm x 209mm. If you order a 100kg bag of cement, it can weigh 99kg or 101kg. If you order a 500l drum of paint, it could be 494 or 504l.

The reason for this is that the tolerances aren’t set by the manufacturers — they’re set by the customer! If you tell them to make something to within 1mm tolerance, then they will do their best to get it within 1mm tolerance.

However, if they don’t have enough time to do so (and most don’t), then they won’t be able to meet your requirements and will have to give reject products away instead (which isn’t good for either party).

Manufacturers try their best to meet your requirements but always keep in mind that they need to turn a profit too!

Are there any finishing processes that need to be carried out after machining is completed ?

Machining is a process of cutting, shaping and forming a material by the use of machine tools.

Machining is used to produce parts that cannot be cast or welded. For example, machining is required to produce gears, shafts and other components that go into engines.

In addition to the machining process, there are other processes that need to be carried out after machining is completed:

1) Drilling holes for fasteners and other purposes.

2) Tapping threads for screws and bolts.

3) Polishing surfaces for aesthetic appeal or to improve wear resistance.

Machining is a process that uses tools to remove material from a workpiece. Machining is typically done with cutting tools such as drills, end mills and saws. The most common type of machining is turning which removes material from the outside of a piece until it reaches its desired shape. Turning can also be used to create holes in the center of a part.