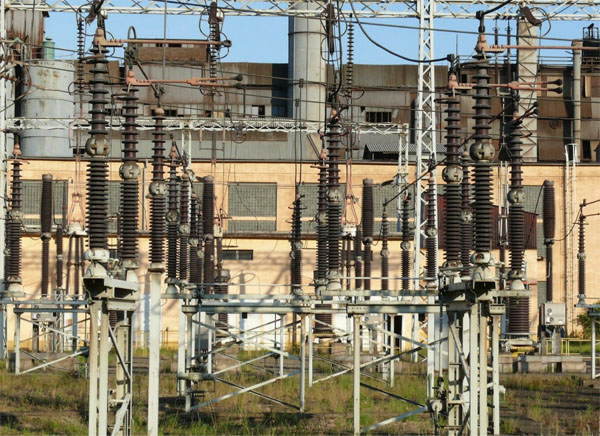

How Transformers Help Restore Power Quickly and Keep Operations Running

By Space Coast Daily // December 3, 2025

Transformers deliver reliable electricity to homes, businesses, and industrial facilities. When power systems encounter failures, storms, or unexpected equipment breakdowns, transformers determine how quickly energy can be restored. Their ability to manage voltage levels and stabilize supply makes them critical to modern grid infrastructure.

Organizations must look for ways to minimize downtime and operational losses and understand how transformers support rapid recovery. Explore the ways transformers function during emergencies and everyday operations so that companies can better prepare for disruptions and strengthen their power resilience.

Rapid Deployment Solutions for Emergency Power Restoration

Utilities rely on flexible response strategies to recover from outages, and transformers provide the foundation for those efforts. Mobile transformer units, modular systems, and temporary installations help crews rebuild service pathways when permanent equipment fails unexpectedly. In many cases, teams deploy emergency transformers replacement solutions to maintain essential functions and repair long-term infrastructure. Professionals who provide these solutions let organizations protect critical equipment and reduce service interruptions, even under challenging field conditions.

Companies that integrate adaptable transformers into their emergency plans shorten repair timelines and avoid costly downtime. This rapid-response capability will guarantee that outages don’t escalate into prolonged operational disruptions. The ability to move and install transformers quickly strengthens overall grid resilience and supports community safety during crises.

How Transformer Design Supports Fast System Recovery

Modern transformers feature advanced engineering that allows them to handle high electrical loads and respond to variable power conditions with remarkable stability. Their robust insulation, cooling technologies, and winding configurations help reduce failure risks during heavy demand or adverse weather.

Manufacturers now incorporate materials and components that can withstand thermal stress and electrical surges more effectively for consistent performance under pressure. These design improvements speed up recovery efforts: damaged or unstable components are less common. When faults do occur, standardized designs make repair or replacement more efficient for service crews. These advances create transformers that contribute to a more reliable grid, helping teams recover faster from unexpected disruptions.

The Role of Monitoring Systems in Preventing Downtime

Real-time monitoring and diagnostic tools help operators detect early signs of transformer stress. Sensors track temperature, oil quality, load patterns, and internal vibrations to identify abnormalities that could lead to equipment failure. With this data, technicians can schedule preventative maintenance at optimal times and reduce the chances of outages that affect broader operations.

Predictive analytics forecast how transformers will perform under upcoming conditions so that utilities prepare accordingly. With these insights at hand, organizations can allocate resources more effectively during emergencies. By preventing failures and enabling informed decisions, monitoring systems improve transformer reliability and support faster recovery after disturbances.

Supporting Critical Infrastructure During Grid Failures

Transformers power hospitals, data centers, manufacturing facilities, and other critical infrastructure that cannot afford extended downtime. When the grid experiences widespread failures, transformers maintain voltage regulation to guarantee that sensitive equipment receives the right level of power.

Backup and redundant transformers are frequently installed in these environments for continuous operation even when primary units fail. This redundancy strategy helps organizations remain operational during severe weather events, cyber incidents, or large-scale outages.

Portable transformers can be brought onsite quickly when emergencies arise, offering temporary stability until permanent repairs are completed. Transformers help organizations avoid disruptions that could endanger safety or cause significant financial loss.

Grid Flexibility Through Modular Transformer Systems

Modular transformer systems offer scalability and adaptability in environments where power needs fluctuate rapidly. These systems can be assembled and configured in various ways to meet changing load demands or support newly installed equipment. Modules can be replaced individually, and repairs become faster and less disruptive than replacing a full-sized transformer unit.

Utilities can use modular systems to expand temporary power capacity during major restoration events. Modular transformers help maintain continuous operations and reduce downtime and operational costs. Their ability to integrate quickly into existing networks further strengthens the grid’s resilience.

Adapting to Natural Disasters with Mobile Transformer Units

When severe storms, floods, or wildfires damage electrical infrastructure, mobile transformer units will restore power. These units arrive pre-assembled on trailers and can be deployed rapidly to affected areas, providing immediate voltage regulation. Their compact design allows crews to install them without extensive site preparation, which speeds up recovery efforts.

Once connected, they stabilize electrical flow and prevent cascading failures across the network. Utilities rely on mobile units to supply power to emergency shelters, temporary command centers, or industrial operations during long repair periods. Their mobility and efficiency help communities recover more quickly after disaster events.

Industrial Continuity During Equipment Failures

Industrial operations depend on stable and consistent electricity, and transformer failures can bring production to a halt. To prevent such interruptions, many facilities implement contingency plans that include backup transformers and streamlined replacement procedures. Maintenance teams can respond immediately when faults occur, minimizing disruptions to manufacturing cycles.

The presence of spare units on-site or nearby means recovery efforts start at once, limiting the impact of equipment downtime. Industries with high power demands use transformers with higher load capacities to reduce strain and prolong service life. Companies that integrate redundancy and quick-swap strategies maintain output levels and safeguard the safety of workers and equipment.

How Coordinated Response Teams Accelerate Power Restoration

Skilled response teams must be equipped with specialized tools to address transformer-related issues quickly. Crews follow carefully coordinated procedures that prioritize safety, efficiency, and clear communication. They can diagnose transformer failures accurately and determine the fastest path to restoration.

Collaboration among electricians, engineers, and grid operators streamlines the repair process during large-scale outages. Insulated lifting devices, hydraulic tools, and precision measurement instruments support rapid and safe installation. Response teams practice these workflows regularly, so that they can execute restoration tasks with minimal delays. Communities and businesses regain power as fast as possible after disruptions.

Transformers restore power quickly and maintain stable operations across a wide range of industries and environments. Their design, flexibility, and integration with modern monitoring systems make them necessary for emergency response and long-term grid reliability. By understanding how transformers support fast recovery and continuous service, organizations can strengthen their readiness for unexpected power challenges and protect their operations.